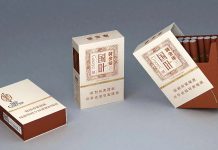

As a brand, it is important to know that custom printing on your packaging boxes attracts more customers. A print on the boxes is the main way a brand distinguishes itself from other brands. Most companies use custom packaging boxes with logo as their product’s signature. The packaging print craft varies from one brand to another, product to another, or even the type of box. Different printing methods are suitable for different box types.

Packaging Boxes Printing Methods

Most people don’t like ordinary things. Packaging without printing on it seems extremely standard. Adding a print on a packaging box gives it an attractive finish. There are a lot of print graphics that one can add to a custom packaging box. Such graphics may be logos, names, and pictures symbolizing a certain brand. Print craft product boxes are a great way of advertising and promoting a brand. There are different printing methods that packaging box manufacturers use to enhance the appearance of the boxes.

Embossing and debossing

Embossing is the process of creating an imprinted graphic outline on the box, while debossing is the process of raising the graphic. The extra layer created during these processes enhances the image’s visualization and makes it distinct. If you intend to have luxury box packaging, embossing and debossing are the printing methods.

Litho laminating

In litho-laminating printing, one must print a graphic on a separate piece of paper before printing it on a packaging box. For people who need to have real images on the box, litho laminating is the style to go for. This printing style produces smooth, clear, and real images. With litho laminating, one can print in six varying colors. This method is also ideal for different packaging box materials.

Silk screen printing

The silk screen printing method is also known as squeegee printing. In silk screen printing, one must use a mesh screen to apply paint on the surface of the packaging box. The mesh screen in this print craft should contain the outline of the stencil image the user wants to print. Silk screen printing involves a lot of work; therefore, it may not be ideal for printing high volumes of packaging boxes.

Digital printing

Like flexo printing, digital printing involves printing directly on the box’s surface. Digital printing allows one to print electronic graphics on different box materials. With this printing style, one does not need dies or printing plates. The simplicity of this method makes it preferable to other printing methods.

Flexo printing

Flexo printing is a 3-shade style that directly applies a print design on the box. The printing style is simple, thus allowing it to be affordable. Most people go for this design due to its versatility. This method utilizes the stamping style to put a graphic on a packaging box by pressing the desired graphic directly on the surface of the package.

Conclusion

The above printing styles come at different costs. A printing method like flexo may cost less since it’s straightforward. However, styles that involve too much work, like silk screen printing, will come at a higher cost. Simple printing styles are also great for high-volume printing, while complex ones are ideal for small-scale printing. Whichever print craft you choose, ensure that it reflects who you are as a brand.